PA6 is recognized as the most widely used and known engineering plastic in the current market. PA6 has the best performance, very tough, even at low temperatures, and high surface hardness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials.

PA6 Nylon is widely substituted for wear parts of mechanical equipment, it’s also used in Shaft sleeve, bearing bush, lining, lining plate, Worm gear, roller copper guide rail, piston ring, seal ring, slide block, Spheric bowl, Pipe, stuffing box, rack, belt pulley, pump rotor, etc.

POM C is a copolymer grade that has the ideal combination of strength, stiffness and wears resistance. It absorbs very little moisture, is easily machinable and is genuinely porosity-free making it the preferred grade for food contact and medical applications. The product exhibits elevated resistance to hydrolysis, strong alkalis and thermal-xi dative degradation when compared to acetal homopolymer. Excellent fatigue resistance and creep resistance. Good abrasion resistance, self-lubricated and friction. High thermal stability, good chemical stability and excellent electrical insulation. And it can be used in temperatures ranging from -50°C to +110°C.

POM C can be used in precision parts that require high stiffness, low friction and excellent dimensional stability. In Machinery industry used to produce gears, springs, bearings, wheels, connecting rod, impeller blades etc.

Other common uses include bearing and lining, roller, conveyor chain, gear, cam, coupler, idler roller, impeller, pump case, gasket and many other

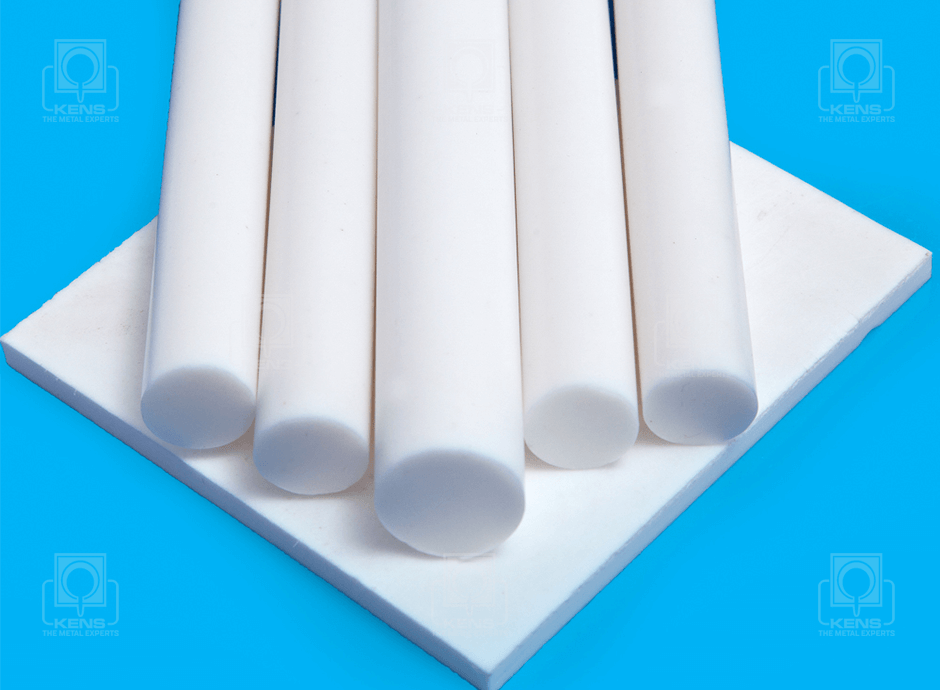

PTFE is polytetrafluoroethylene substrate modified by adding enhanced PTFE glass fiber filled, it has extremely superior properties: high and low temperature (-200 °C -260 °C), corrosion resistance (acid, alkali, aqua regia, etc.), weather-resistance, high insulation, high lubrication, non-sticking, non-toxic and other good features. This self-lubricating material provides a low friction coefficient, and is ideally suited for the manufacture of corrosion-resistant gaskets & seals. PTFE was the first fluorocarbon.

Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

Abrasion resistance: can be used as a self-lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc.

Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc.