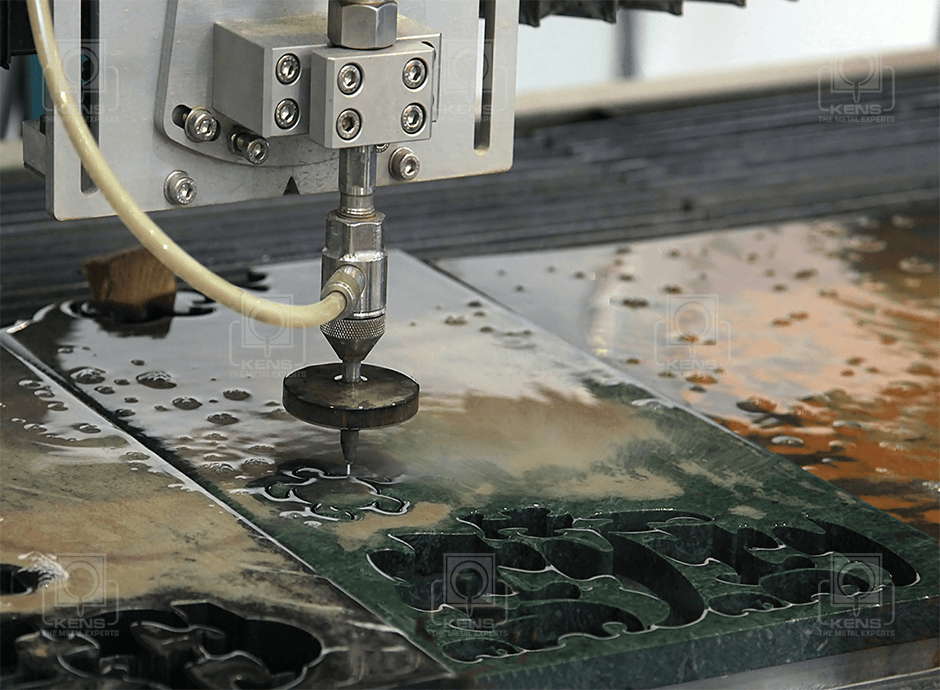

Water Jet Cutter CNC is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance, in this case granite. An important benefit of the water jet is the ability to cut material without interfering with its inherent structure, as there is no heat-affected zone (HAZ). Minimizing the effects of heat allows metals to be cut without harming or changing intrinsic properties. Sharp corners, bevels, pierce holes, and shapes with minimal inner radii are all possible.

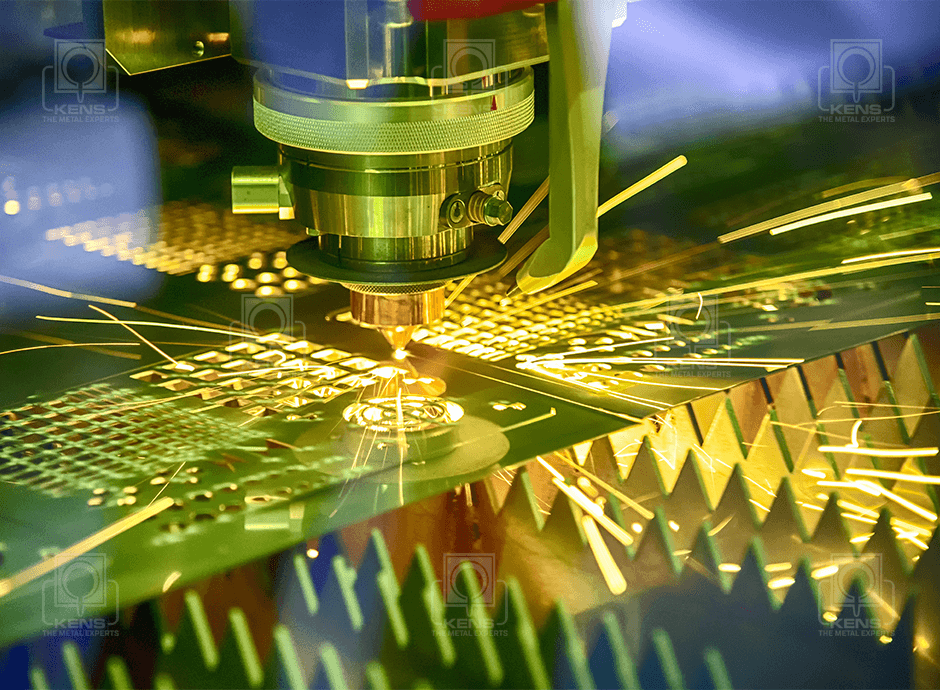

Laser CNC is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. It works by directing the output of a high-power laser most commonly through optics. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

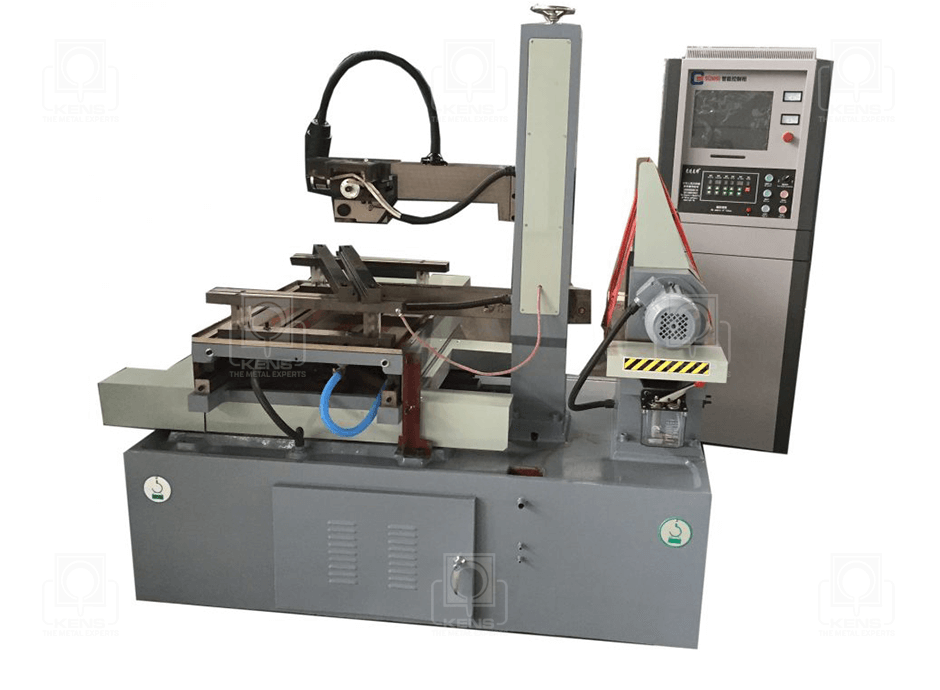

Also known as wire-cut Electric Discharge Machine (EDM) for the purpose of making tools (dies) from hardened steel. The tool electrode in wire EDM is simply a thin single-strand metal wire, usually brass, is fed through the workpiece, submerged in a tank of dielectric fluid, typically deionized water. It is typically used to cut plates as thick as 300mm and to make punches, tools, and dies from hard metals that are difficult to machine with other methods.

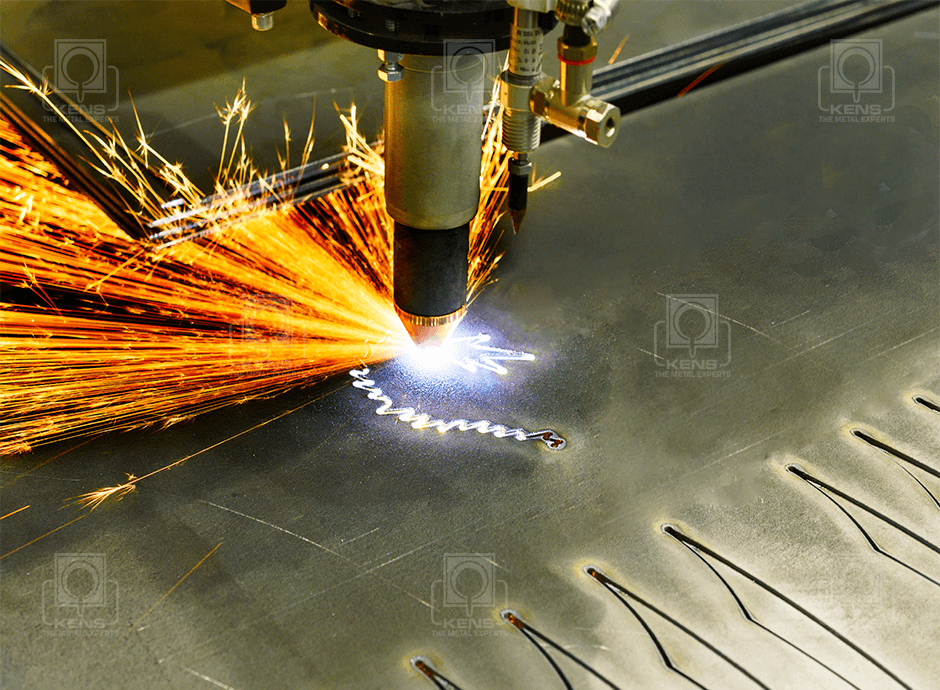

Plasma CNC is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. The basic process involves creating an electrical channel of superheated, electrically ionized gas i.e. plasma from the plasma cutter itself, through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter via a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material being cut) which is blown through a focused nozzle at high speed toward the work piece. Typical materials cut include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. is an effective way of cutting thin and thick materials alike.

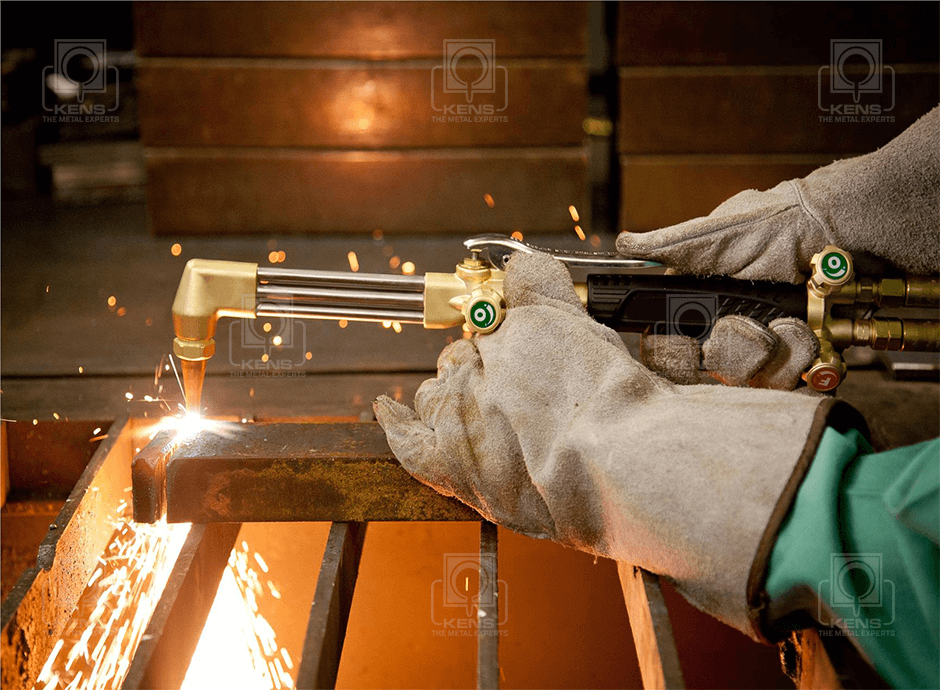

Oxy-gas Cut CNC is a combustion process using oxygen/fuel gas flame. The heating flame brings the material up to its ignition temperature. Then a jet of Oxygen at least 99,5 % pure is blown onto the heated spot. The Oxygen jet oxidizes the metal. The torch is moved and a narrow cutting kerf is created, removing the slag from the kerf. The quality of the cut depends on the surface condition of the material, cut-velocity and thickness.

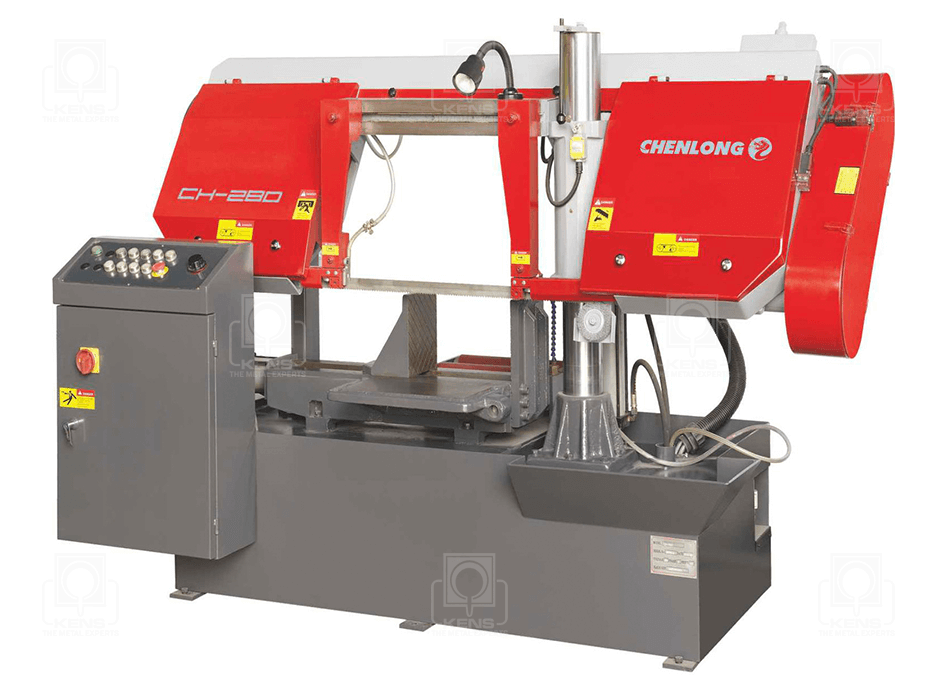

Horizontal and Vertical Bandsaw is a saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material.

Shearing is defined as the mechanical cutting of large sheets of metal into smaller pieces of predetermined sizes. A shearing operation that completes an entire perimeter is known as blanking, with the resulting workpiece being called a blank.

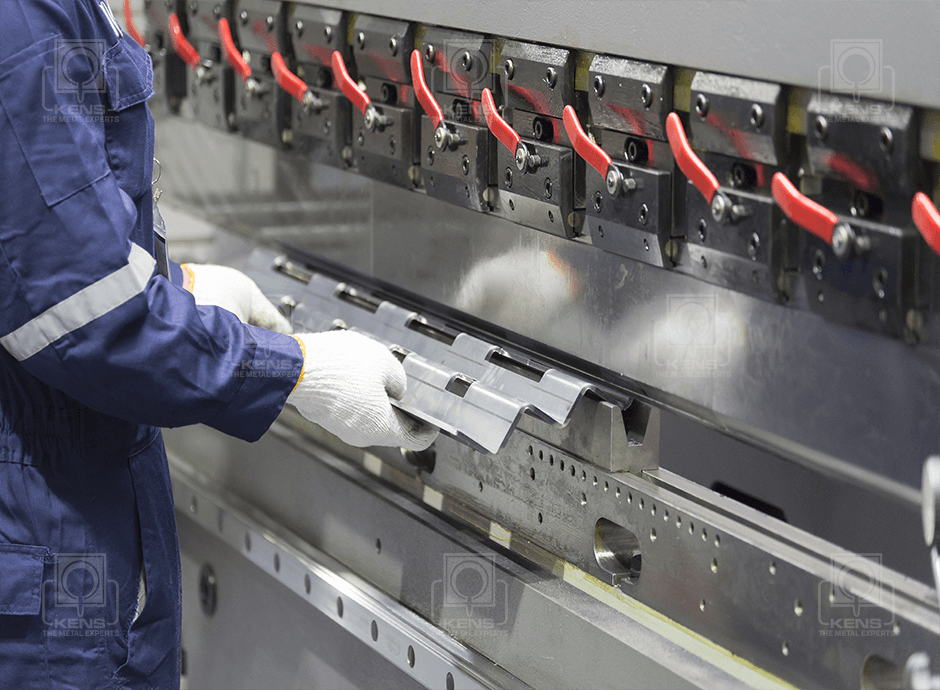

Bending is defined as the creation of three dimensional shapes out of two-dimensional stock. There is virtually an unlimited variety of shapes that can be produced in both sheet metal and plate thickness’ by bending.