Aluminium 6063 is a low to medium strength aluminium alloy, but can be used to create more complex shapes and sections. It exhibits good corrosion resistance and a high surface finish and can be anodised to produce different surface finishes. Commonly referred to as an architectural alloy, it is normally used in intricate extrusions. It has a good surface finish, high corrosion resistance, is readily suited to welding and can be easily anodised. Most commonly available as T6 temper, in the T4 condition it has good formability.

| Element | Manganese (Mn) | Iron (Fe) | Magnesium (Mg) | Silicon (Si) | Zinc (Zn) | Copper (Cu) | Aluminium (Al) |

|---|---|---|---|---|---|---|---|

| % Present | 0.0 - 0.10 | 0.0 - 0.35 | 0.45 - 0.90 | 0.20 - 0.60 | 0.0 - 0.10 | 0.0 - 0.10 | Balance |

6063 is typically used in: Hand railing, furniture and various extruded architectural profiles such as window frames, doors & roofs, Sign frames, Shop Fittings and Irrigation tubing.

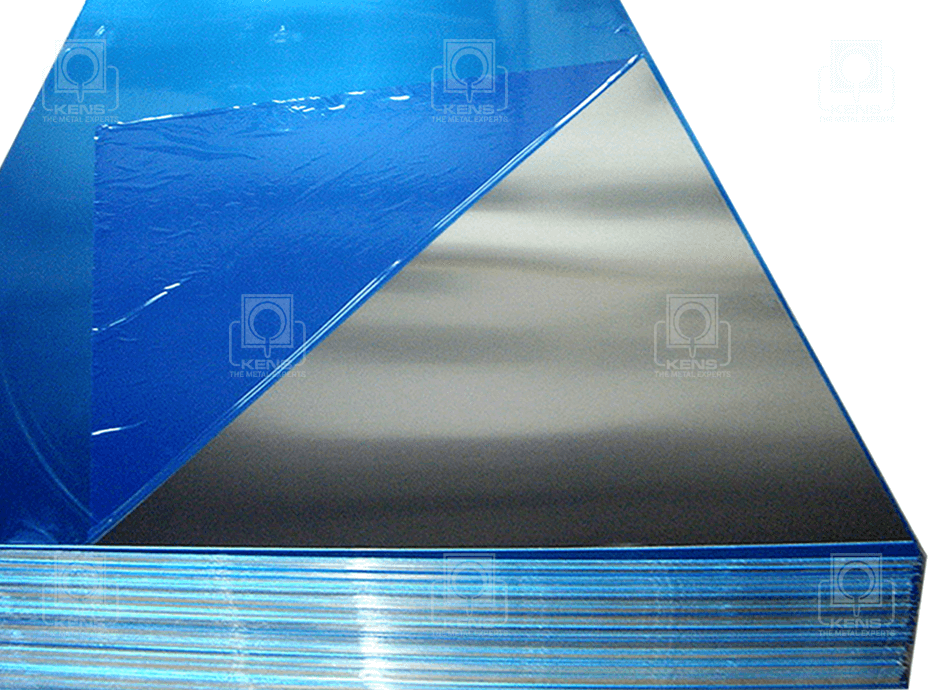

Aluminum alloy 1050 is a popular grade of aluminum for general sheet metal work where moderate strength is required. It is known for its excellent corrosion resistance, high ductility and highly reflective finish. It has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.

| Element | Cu | Mg | Si | Fe | Mn | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| % Present | 0 - 0.05 | 0 - 0.05 | 0 - 0.25 | 0 - 0.4 | 0 - 0.05 | 0 - 0.07 | 0 - 0.05 | Balance |

Aluminum 1050 is commonly used for Chemical process plant equipment, Food industry containers, Pyrotechnic powder, Architectural flashings, Lamp reflectors, Cable sheathing

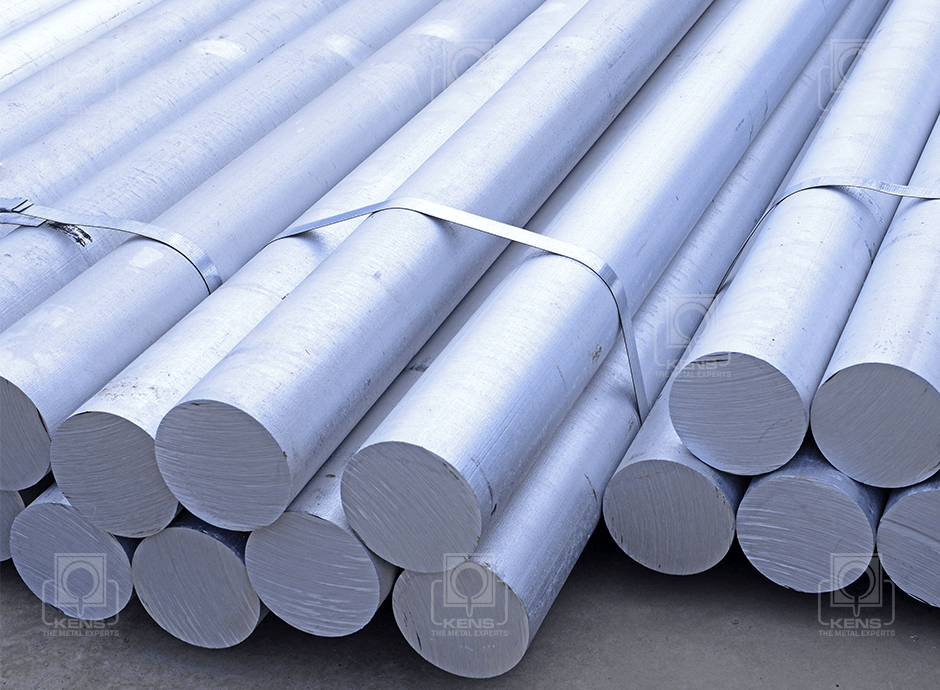

7075 aluminium alloy is an aluminium alloy, with zinc as the primary alloying element. It is strong, with a strength comparable to many steels, and has good fatigue strength and average machinability. When machined it produces curled or easily broken chips but results in a good surface finish. It displays high hardness and strength but poor weldability and corrosion resistance. It is commonly used in the aerospace industry and typically available in rounds and rectangles.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Ai |

|---|---|---|---|---|---|---|---|---|---|

| 0.40 | 0.50 | 1.2 - 2.0 | 0.30 | 2.1 - 2.9 | 0.18 - 0.28 | 5.1 - 6.1 | 0.15 | 0.15 | The rest |

Aluminum 7075 alloy is mainly used in manufacturing aircraft and other aerospace applications, rock climbing equipment, bicycle components, inline skating-frames and hang glider airframes are commonly made from 7075 aluminum alloy.